Resin-SZUV-S9006-siab tenacity

Taw qhia txog 3D Printing Materials

Yam ntxwv

SZUV-S9006

KHOOM PLIG

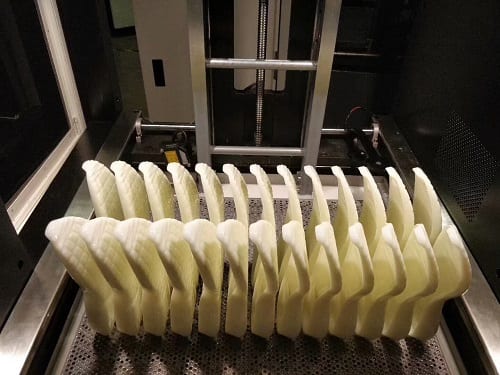

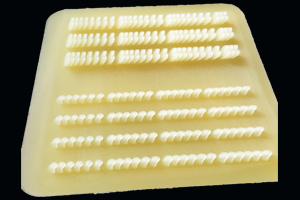

SZUV-S9006 yog ABS zoo li SL cob uas muajsiab toughnessnta. Nws yog tsim los rau lub xeev SLA tshuab luam ntawv. SZUV-S9006 tuaj yeem siv rau hauv cov qauv tswv, cov qauv tswv yim, cov khoom sib dhos thiab cov qauv ua haujlwm hauv kev lag luam tsheb, kev kho mob thiab cov khoom siv hluav taws xob. Qhov chaw durability lub tsev nrog SZUV-S9006 yog tshaj 6.5 hli.

TYPICALNTA

-Liquid resin lub nruab nrab viscosity, yog li yooj yim recoating, yooj yim los ntxuav qhov chaw thiab tshuab

- Txhim kho lub zog khaws cia, txhim kho qhov ntev tuav ntawm qhov chaw nyob rau hauv qhov chaw ntub dej

-xav tau qhov tsawg kawg nkaus ua tiav

-Lub neej ntev hauv tshuab

-Tsawghauv qab contraction

TYPICALTXOJ CAI

-Xav tau lub sijhawm ua tiav tsawg dua, yooj yim dua tom qab kho

-Bulid qhov tseeb thiab siab tawv qhov chaw nrog kev txhim kho qhov ruaj khov

-Kev tswj tau zoo rau lub tshuab nqus tsev casting qhov chaw

- Tsawg shrinkage thiab zoo tiv thaiv yellowing

- Cov xim dawb zoo nkauj

- Cov khoom siv SLA zoo tshaj plaws

Nco tseg: qhov kub ntawm szuv-s9006 yuav tsum tsis txhob siab dhau. Thov siv nws hauv qab 25 ℃. Cov av noo txheeb ze rau kev siv thiab khaws cia yuav tsum yog qis dua 38RH%.

Ib txhia ntawm kuv qhov project

Kev kawm

Tes Pwm

Auto Parts

Ntim Design

Art Design

Kho mob

Physical Properties (Liquid)

| Qhov tshwm sim | Dawb |

| Qhov ntom | 1.11-1.15g / cm33@ 25 ℃ |

| viscosity | 230 ~ 290cps @ 26 ℃ |

| Dp | 0.13 ~ 0.145 hli |

| Ec | 9.5 ~ 10.5 mJ/cm2 |

| Lub tsev txheej thickness | 0.05 ~ 0.12 hli |

Mechanical Properties (Tom qab kho tau)

| Kev ntsuas | KEV TIV THAIV | VALUE |

| 90-feeb UV tom qab kho | ||

| Hardness, Ntug D | ASTM D 2240, ASTM D 2240, ASTM D 2240 | 75-85 : kuv |

| Flexural Modulus, Mpa | ASTM D 790 Cov khoom siv raw khoom | 2,592-2,675 Ib |

| Flexural zog, Mpa | ASTM D 790 Cov khoom siv raw khoom | 63-70 : kuv |

| Tensile modulus, MPa | ASTM D 638 (Tshooj 638) | 2,489-2,595 Ib |

| Tensile zog, MPa | ASTM D 638 (Tshooj 638) | 36-53 : kuv |

| Elongation thaum so | ASTM D 638 (Tshooj 638) | 15-25% |

| Poisson tus ratio | ASTM D 638 (Tshooj 638) | 0.4-0.44 Nws |

| Kev cuam tshuam lub zog notched Izod, J / m | ASTM D 256 | 45-70 : kuv |

| Thaum tshav kub kub deflection, ℃ | ASTM D 648 @ 66 PSI | 38-50 : kuv |

| Kev hloov iav, Tg | DMA, E”peak | 40-54 : kuv |

| Coefficient ntawm thermal expension | TMA (T | 90-102 * E-6 |

| Qhov ceev, g / cm33 | 1.12-1.18 Nws | |

| Dielectric tsis tu ncua 60 Hz | ASTM D 150-98 Kev ntsuas kev ntsuas | 4.2-5.0 |

| Dielectric tsis tu ncua 1 kHz | ASTM D 150-98 Kev ntsuas kev ntsuas | 3.3-4.2 |

| Dielectric Constant 1 MHz | ASTM D 150-98 Kev ntsuas kev ntsuas | 3.2-4.0 |

| Dielectric zog kV / mm | ASTM D 1549-97 a | 12.8-16.1 Nws |