Resin SZUV-T1120-siab kub kuj

Kev Taw Qhia General

Yam ntxwv:

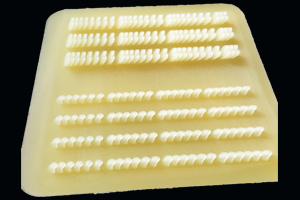

SZUV-T1120 yog cov xim daj SL uas muaj kev ua haujlwm tsis zoo thermal. Nws tuaj yeem tiv taus qhov kub thiab txias tshaj 200 ℃ ntawm lub sijhawm luv luv thiab 120 ℃ ntawm lub sijhawm ntev. Nws yog tsim los tuav ntau yam kev kub siab thiab kev sim tsis zoo.

Cov yam ntxwv

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

SZUV-T1120 tuaj yeem sawv ntsug ntawm cov av noo, dej thiab cov kuab tshuaj, xws li roj av, cov kua dej sib kis, roj thiab cov dej txias. Nrog rau nws qhov tsis sib haum xeeb ua kom sov, nws yog qhov tsim nyog rau kev khiav, HVAC, teeb pom kev zoo, cuab yeej, molding thiab cua qhov kev xeem daim ntawv thov.

- Ua kom nrawm dua thiab txhim kho sai dua

Los ntawm kev muab cov zis tawm sai thiab qhov chaw nrog tus du, yooj yim-rau-kawg nto, SZUV-T1120 tuaj yeem ua tiav koj qhov project los ntawm kev kos duab mus rau qhov chaw sim hauv lub sijhawm luv tshaj.

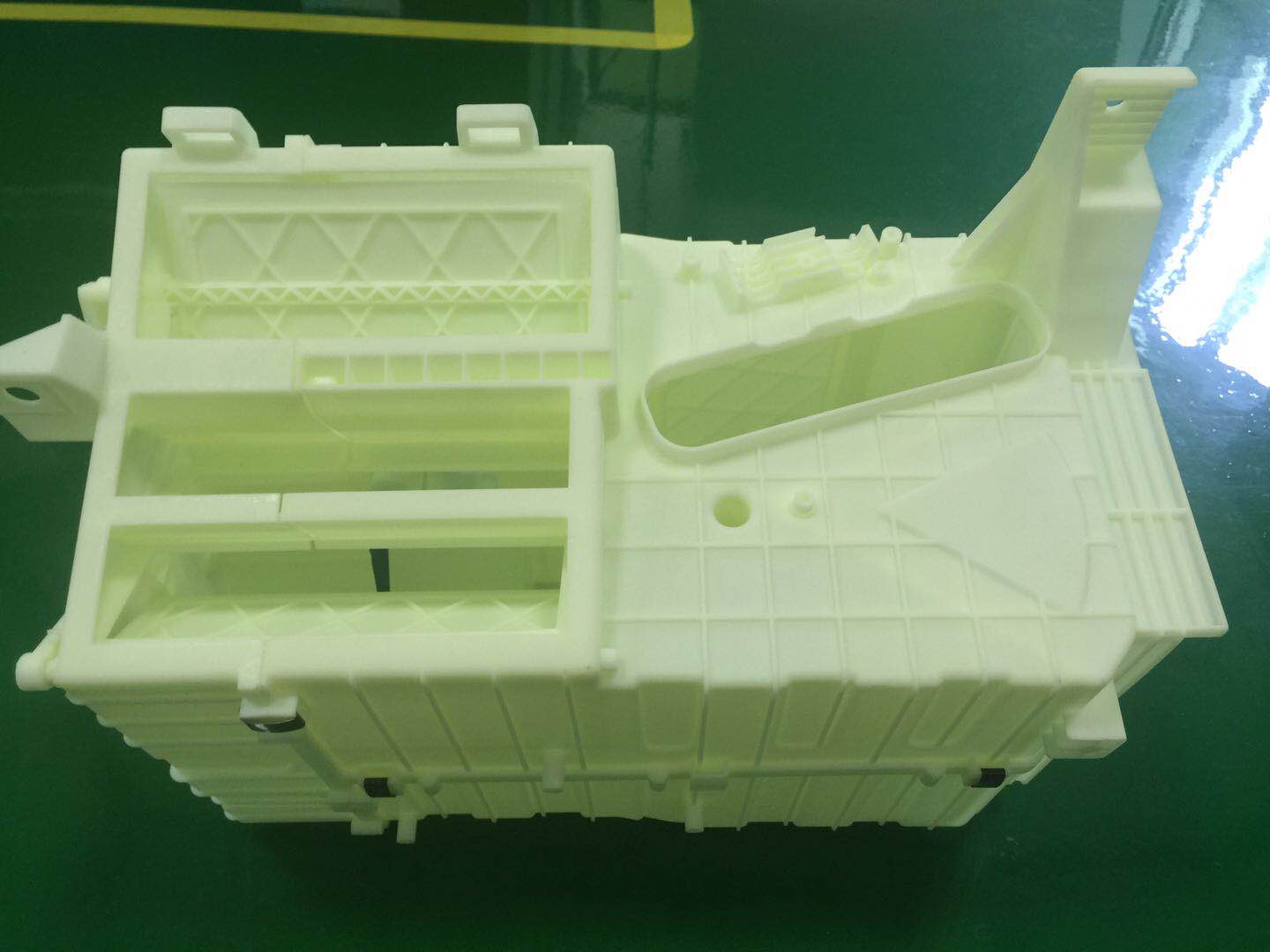

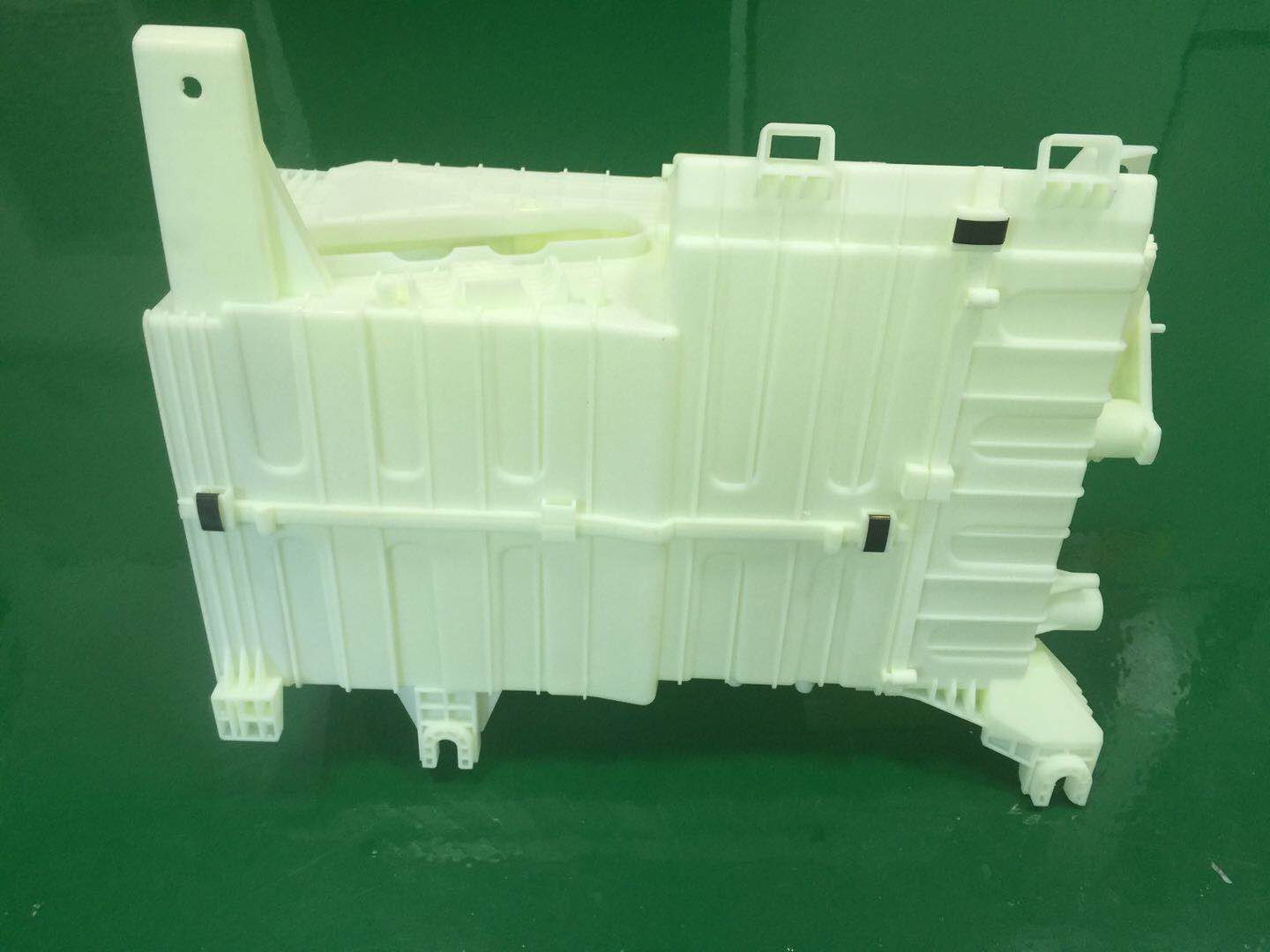

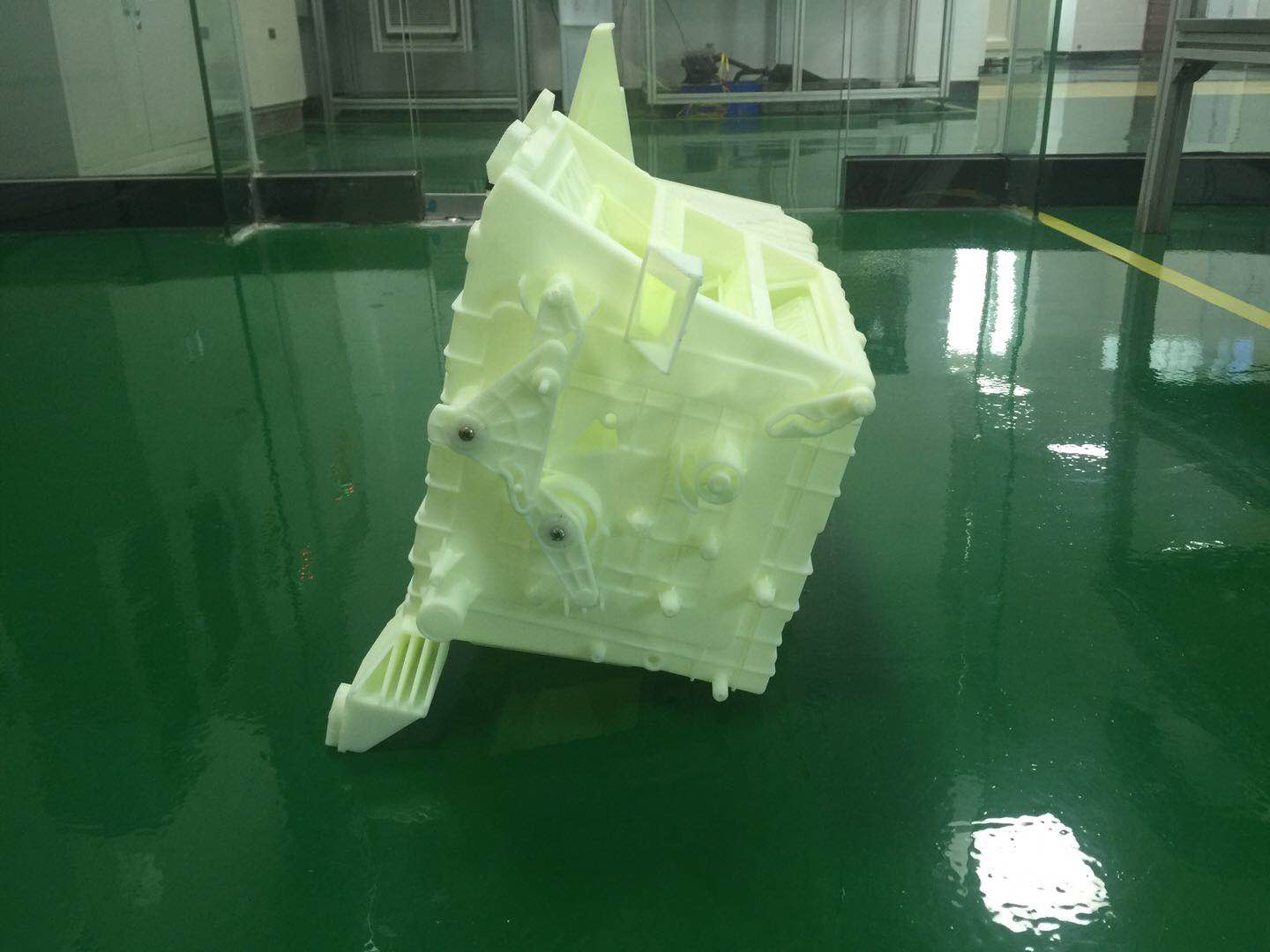

Daim ntawv thov Case

-Nyob rau hauv-lub hood testing

- Kub kub RTV molding

- Cua tunnel kuaj

- Kev ntsuas teeb pom kev zoo

-Composite autoclave tooling

-HVAC tivthaiv kuaj

- Kev ntsuas kev noj tshuaj manifold

- Orthodontics

KEV PAB CUAM

Kev kawm

Tes Pwm

Auto Parts

Ntim Design

Art Design

Kho mob

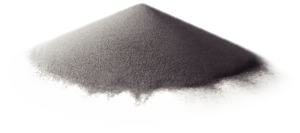

Lub cev muaj zog (kua)

| Qhov tshwm sim | dawb |

| Qhov ntom | 1.13g / cm33@ 25 ℃ |

| viscosity | 400 ~ 480 cps @ 29 ℃ |

| Dp | 0.152 hli |

| Ec | 7.6 mJ/cm2 |

| Lub tsev txheej thickness | 0.05 ~ 0.12 hli |

MECHANICAL PROPERTIES (Post-CURED)

| Kev ntsuas | Txoj Kev Xeem | Tus nqi | |

| 90-feeb UV tom qab kho | 90-feeb UV + 2 teev @ 160 ℃ thermal tom qab kho | ||

| Hardness, Ntug D | ASTM D 2240, ASTM D 2240, ASTM D 2240 | 87 | 91 |

| Flexural Modulus, Mpa | ASTM D 790 Cov khoom siv raw khoom | 2678-3186 ib | 3502-3631 Ib |

| Flexural zog, Mpa | ASTM D 790 Cov khoom siv raw khoom | 60-80 | 90-101 : kuv |

| Tensile modulus, MPa | ASTM D 638 (Tshooj 638) | 2840-3113 : kuv | 3484-3771 Ib |

| Tensile zog, MPa | ASTM D 638 (Tshooj 638) | 58-67 : kuv | 50-62 : kuv |

| Elongation thaum so | ASTM D 638 (Tshooj 638) | 4-8% | 4-6% |

| Impact zog, notched lzod, J / m | ASTM D 256 | 18-30 | 16-23 |

| Thaum tshav kub kub deflection, ℃ | ASTM D 648 @ 66 PSI | 81 | 98 |

| Kev hloov iav, Tg, ℃ | DMA, E'peak | 100 | 111 |

| Coefficient ntawm thermal expansion, E6 / ℃ | TMA (T | 79 | 86 |

| Thermal conductivity, W / m ℃ | 0.171 ib | ||

| Qhov ntom | 1.24 | ||

| Kev nqus dej | ASTM D 570-98 Cov khoom lag luam | 0.49% | 0.46% |

Mechanical Properties ntawm cov khoom tom qab kho

| Kev ntsuas | KEV TIV THAIV

|

| VALUE |

|

|

| 90-feeb UV tom qab kho | 90 feeb UV + 2 teev @ 160℃thermaltom qab kho |

| Hardness, Ntug D | ASTM D 2240, ASTM D 2240, ASTM D 2240 | 87 | 91 |

| Flexural Modulus, Mpa | ASTM D 790 Cov khoom siv raw khoom | 2678-3186 ib | 3502-3631 Ib |

| Flexural zog, Mpa | ASTM D 790 Cov khoom siv raw khoom | 60-80 | 90-101 : kuv |

| Tensile modulus, MPa | ASTM D 638 (Tshooj 638) | 2840-3113 : kuv | 3484-3771 Ib |

| Tensile zog, MPa | ASTM D 638 (Tshooj 638) | 58-67 : kuv | 50-62 : kuv |

| Elongation thaum so | ASTM D 638 (Tshooj 638) | 4-8% | 4-6% |

| Impact zog, notched lzod, J / m

| ASTM D 256

| 18-30 Nws

| 16-23 : kuv |

| Thaum tshav kub kub deflection,℃

| ASTM D 648 @ 66 PSI

| 81 | 98

|

| Kev hloov iav, Tg ,℃ | DMA,E”ncov

| 100 | 111

|

| Coefficient ntawm thermal expansion, E6 /℃ | TMA(T)

| 79

| 86

|

| Thermal conductivity, W / m.℃ |

| 0.171 ib |

|

| Qhov ntom |

| 1.24 |

|

| Kev nqus dej | ASTM D 570-98 Cov khoom lag luam | 0.49% | 0.46% |