Resin-SZUV-S9006-high tenacity

Introduction of 3D Printing Materials

Characteristics

SZUV-S9006

PRODUCT DESCRIPTION

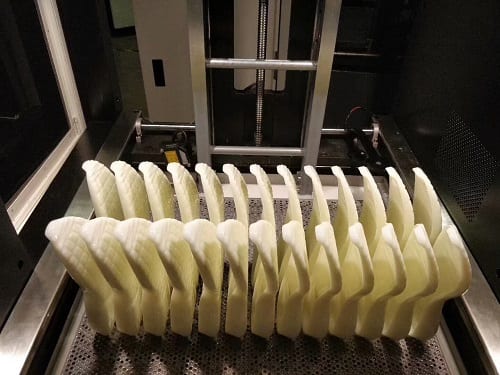

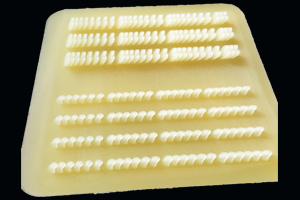

SZUV-S9006 is an ABS like SL resin which has high-toughness features. It is designed for solid state SLA printers. SZUV-S9006 can be applied in master patterns, concept models, assembly parts and functional prototypes in the field of automotive, medical and consumer electronics industries. The parts durability building with SZUV-S9006 is over 6.5months.

TYPICAL FEATURES

-Liquid resin's medium viscosity, so easy recoating, easy to clean parts and machines

-Improved strength retained, improved dimensions retention of parts in humid condition

-need minimal part finishing

-Long shelf life in machine

-Low bottom contraction

TYPICAL BENEFITS

-Need less part finishing time, easier post-curing

-Bulid accurate and high tough parts with an improved dimensional stability

-High quality controls for vacuum casting parts

-Low shrink and good resistance to yellowing

-Magnificent white color

-Outstanding machinable SLA material

Note: the temperature of szuv-s9006 should not be too high. Please use it below 25℃. The relative humidity for use and storage must be under 38RH%.

SOME OF MY PROJECTS

Education

Hand Molds

Auto Parts

Packaging Design

Art Design

Medical

Physical Properties (Liquid)

| Appearance | White |

| Density | 1.11-~1.15g/cm3 @ 25 ℃ |

| Viscosity | 230~290cps @ 26 ℃ |

| Dp | 0.13~0.145 mm |

| Ec | 9.5~10.5 mJ/cm2 |

| Building layer thickness | 0.05~0.12mm |

Mechanical Properties (Post-Cured)

| MEASUREMENT | TEST METHOD | VALUE |

| 90-minute UV post-cure | ||

| Hardness, Shore D | ASTM D 2240 | 75-85 |

| Flexural modulus, Mpa | ASTM D 790 | 2,592-2,675 |

| Flexural strength, Mpa | ASTM D 790 | 63-70 |

| Tensile modulus, MPa | ASTM D 638 | 2,489-2,595 |

| Tensile strength, MPa | ASTM D 638 | 36-53 |

| Elongation at break | ASTM D 638 | 15-25% |

| Poisson’s Ratio | ASTM D 638 | 0.4-0.44 |

| Impact strength notched Izod, J/m | ASTM D 256 | 45-70 |

| Heat deflection temperature, ℃ | ASTM D 648 @66PSI | 38-50 |

| Glass transition,Tg | DMA,E”peak | 40-54 |

| Coefficient of thermal expension | TMA(T<Tg) | 90~102*E-6 |

| Density, g/cm3 | 1.12-1.18 | |

| Dielectric Constant60 Hz | ASTM D 150-98 | 4.2-5.0 |

| Dielectric Constant 1 kHz | ASTM D 150-98 | 3.3-4.2 |

| Dielectric Constant1 MHz | ASTM D 150-98 | 3.2-4.0 |

| Dielectric StrengthkV/mm | ASTM D 1549-97a | 12.8-16.1 |