Handheld 3d Scanner- 3DSHANDY-41LS

Introduction of handheld laser 3D scanner

3DSHANDY-41LS Characteristics

3DSHANDY-41LS is a handheld 3d scanner with light weight (0.92kg) and is easy to carry.

26 laser lines + additional 1 beam scanning deep hole + additional 14 beams to scan details, a total of 41 laser lines.

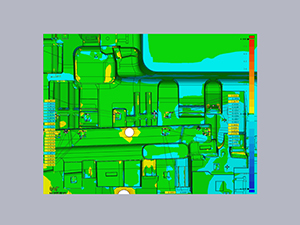

Fast scanning speed, high precision, strong stability, dual industrial cameras, automatic marker splicing technology and self-developed scanning software, ultra-high scanning accuracy and work efficiency.

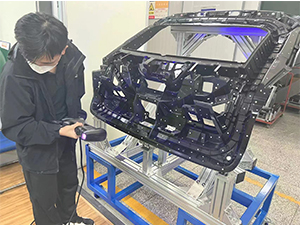

This product has been widely used in the field of reverse engineering and three-dimensional inspection. The scanning process is flexible and convenient, suitable for various complex application scenarios.

● Portable design

Small and portable, easy to carry, handheld design for arbitrary scanning

● Extensive scanning applications

It can be used in various environments and three-dimensional modeling of the surface of different sizes of workpieces. One machine has multiple functions.

● Easy to learn and understand

Those who have no experience in operation can master various operations and calibration procedures proficiently after training

● High efficiency

The output point efficiency of a single frame is increased by more than 3 times, and the measurement rate is as high as 1.6 million measurements per second

● High adaptability

A variety of scanning modes are intelligently guided, black, reflective materials and multi-color can be easily dealt with, and the range is more adaptable

● Detail scan

The resolution of fine mode is up to 0.01mm, the real-time rendering speed and effect are optimized, and the details of the scanning process are clearly visible

● Reduced preliminary work

Reduced number of target reflection marking points

● Scanning format

Scanning format up to 600×550mm

Application Cases

Automobile Industry

Competitive product analysis

· Automobile modification

· Decoration customisation

· Modeling and design

· Quality control and parts inspection

· Simulation and finite element analysis

Tooling Casting

· Virtual assembly

· Reverse engineering

· Quality control and inspection

· Wear analysis and repair

· Jigs and fixtures design, adjustment

Aeronautics

· Rapid prototyping

· MRO and damage analysis

· Aerodynamics & stress analysis

· Inspection & adjustment of parts installation

3D Printing

· Molding inspection

· Reverse design of molding to create CAD data

· End products comparison analysis

· Scanned data can be used for 3D printing directly

Other Area

· Education and scientific research

· Medical and health

· Reverse design

· Industrial design

| Product model | 3DSHANDY-41LS | ||

| Light source | 41 blue laser lines (wavelength: 450nm) | ||

| Measuring speed | 2,570,000points/s | ||

| Scanning mode | Standard mode | Deep hole model | Precision mode |

| 26 crossed blue laser lines | 1 blue laser line | 14 parallel blue laser lines | |

| Data precision | 0.02mm | 0.02mm | 0.01mm |

| Scanning distance | 370mm | 370mm | 200mm |

| Scanning depth of field | 550mm | 550mm | 200mm |

| Resolution | 0.01mm (max) | ||

| Scanning area | 600×550mm (max) | ||

| Scanning range | 0.1-10 m (expandable) | ||

| Volume precision | 0.02+0.03mm/m | ||

| 0.02+0.015mm/m Combined with HL-3DP 3D photogrammetry system (optional) | |||

| Support for data formats | asc, stl, ply, obj, igs, wrl, xyz, txt etc., customizable | ||

| Compatible software | 3D Systems (Geomagic Solutions), InnovMetric Software (PolyWorks), Dassault Systemes (CATIA V5 and SolidWorks), PTC (Pro/ENGINEER), Siemens (NX and Solid Edge), Autodesk (Inventor, Alias, 3ds Max, Maya, Softimage), etc. | ||

| Data transmission | USB3.0 | ||

| Computer configuration (optional) | Win10 64-bit; Video memory: 4G; processor: I7-8700 or above; memory: 64 GB | ||

| Laser safety level | ClassⅡ (Human eye safety) | ||

| Authentication number (Laser certificate): LCS200726001DS | |||

| Equipment weight | 920g | ||

| External dimension | 290x125x70mm | ||

| Temperature / humidity | -10-40℃; 10-90% | ||

| Power source | Input:100-240v, 50/60Hz, 0.9-0.45A; Output: 24V, 1.5A, 36W (max) | ||