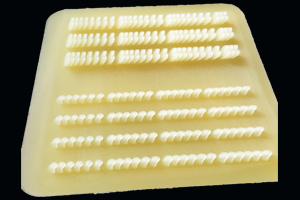

Resin-SZUV-W8006-exquisite white

Introduction of 3D Printing Materials

Characteristics

SZUV-W8006

PRODUCT DESCRIPTION

SZUV-W8006 is an ABS like SL resin which has accurate and durable features. It is designed for solid state SLA platforms. SZUV-W8006 can be applied in master patterns, concept models, general parts and functional prototypes in the field of automotive, medical and consumer electronics industries. The parts durability building with SZUV-W8006 is over 6.5 months.

TYPICAL FEATURES

-Liquid resin is medium viscosity, so easy for recoating, easy to clean parts and machines

-Improved strength retained, improved dimensions retention of parts in humid condition

-Need minimal part finishing

-Long shelf life in machine

TYPICAL BENEFITS

-Need less part finishing time, easier post-curing

-Building accurate and high tough parts with an improved dimensional stability

-High quality controls for vacuum casting parts

-Low shrink and good resistance to yellowing

-Magnificent white color

-Outstanding machinable SLA material

Physical Properties – Liquid Material

| Appearance | White |

| Density | 1.13g/cm3 @ 25 ℃ |

| Viscosity | 376 cps @ 27 ℃ |

| Dp | 0.148 mm |

| Ec | 7.8 mJ/cm2 |

| Building layer thickness | 0.1mm |

Note: the temperature of szuv-w8006 should not be too high. Please use it below 25℃. Recommended temperature for use and preservation is 18-25 ℃.

Handling And Storage

(1) Operation treatment technical measures

Avoid contact with eyes, skin and clothing. Don't inhaling mist or steam, don't accidentally swallow, keep container tightly closed after the thorough cleaning.

(2) Partial or full ventilation, maintain adequate ventilation

(3) Safe handling matters needing attention No smoke, no fire

(4) Safe storage conditions

Stored in a cool, well-ventilated place, away from heat, sparks and flames. Keep container tightly closed until it is put into use.

(5) packaging container and material

In the process of custody, please do not transfer to other containers. Don't fall back to the original containers of products that will be used.

Application Cases

Education

Rapid prototype

Auto Parts

Constructional design

Art Design

Medical

Physical Properties (Liquid)

| Appearance | White |

| Density | 1.13g/cm3 @ 25 ℃ |

| Viscosity | 376 cps @ 27 ℃ |

| Dp | 0.148 mm |

| Ec | 7.8 mJ/cm2 |

| Building layer thickness | 0.1mm |

Mechanical Properties (Post-Cured)

| MEASUREMENT | TEST METHOD |

VALUE |

| 90-minute UV post-cure | ||

| Hardness, Shore D | ASTM D 2240 | 87 |

| Flexural modulus, Mpa | ASTM D 790 | 2,592-2,675 |

| Flexural strength, Mpa | ASTM D 790 | 70- 75 |

| Tensile modulus, MPa | ASTM D 638 | 2,599-2,735 |

| Tensile strength, MPa | ASTM D 638 | 39-56 |

| Elongation at break | ASTM D 638 | 13 -20% |

| Poisson’s Ratio | ASTM D 638 | 0.4-0.43 |

| Impact strength notched Izod, J/m | ASTM D 256 | 35 - 45 |

| Heat deflection temperature, ℃ | ASTM D 648 @66PSI | 62 |

| Glass transition, Tg,℃ | DMA,E”peak | 73 |

| Coefficient of thermal expansion, /℃ | TMA(T<Tg) | 95*E-6 |

| Density, g/cm3 | 1.16 | |

| Dielectric Constant 60 Hz | ASTM D 150-98 | 4.6 |

| Dielectric Constant 1 kHz | ASTM D 150-98 | 3.9 |

| Dielectric Constant 1 MHz | ASTM D 150-98 | 3.6 |

| Dielectric Strength kV/mm | ASTM D 1549-97a | 14.9 |

Note: the temperature of szuv-w8006 should not be too high. Please use it below 25℃. Recommended temperature for use and preservation is 18-25 ℃.