Ceramic 3D Printer 3DCR-600

Introduction to Ceramic 3D Printers

3DCR-300 is a ceramic 3d printer that adopts SL(stereo-lithography) technology.

It possesses features such as high forming precision, rapid printing speed of complex parts, low cost for small-scale production, and so on.

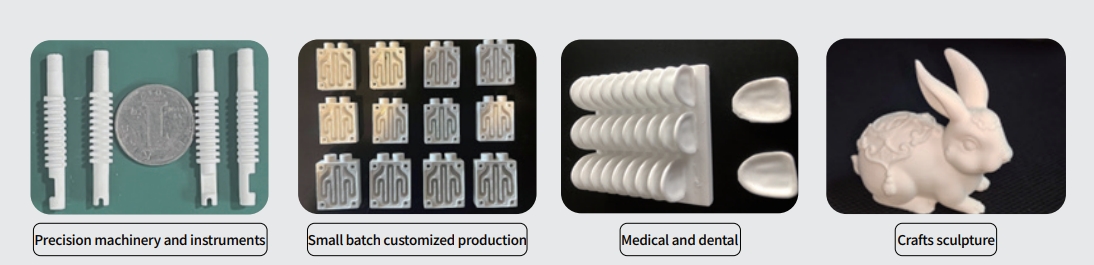

3DCR-300 can be used in aerospace industry, automobile industry, chemical reaction container production, electronic ceramics production, medical fields, arts, high-end customized ceramic products, and more.

Key Features

Piston Sunken Tank

The amount of slurry required depends on the print height; even small amounts of slurry can also be printed.

Innovative Blade Technology

Adopts elastic avoidance tech nology; if encounter occasional impurities in the process of spreading material, the blade can jump up to avoid print failure caused by jamming.

Innovative Slurry Mixing And Circulation Filtration System

Solve the problem of slurry precipita tion and realize the automatic filtration of impurities, so that the printer can continuously work, realize unin terrupted multi-batch printing.

Laser Level Detection And Control

Able to accurately monitor the liquid level changes during the ceramic printing process and adjust in real time to maintain a stable liquid level; effectively prevents uneven spreading and scratching problems caused by unstable liquid level, thus improving the reliability of the printing process and the quality of the finished product.

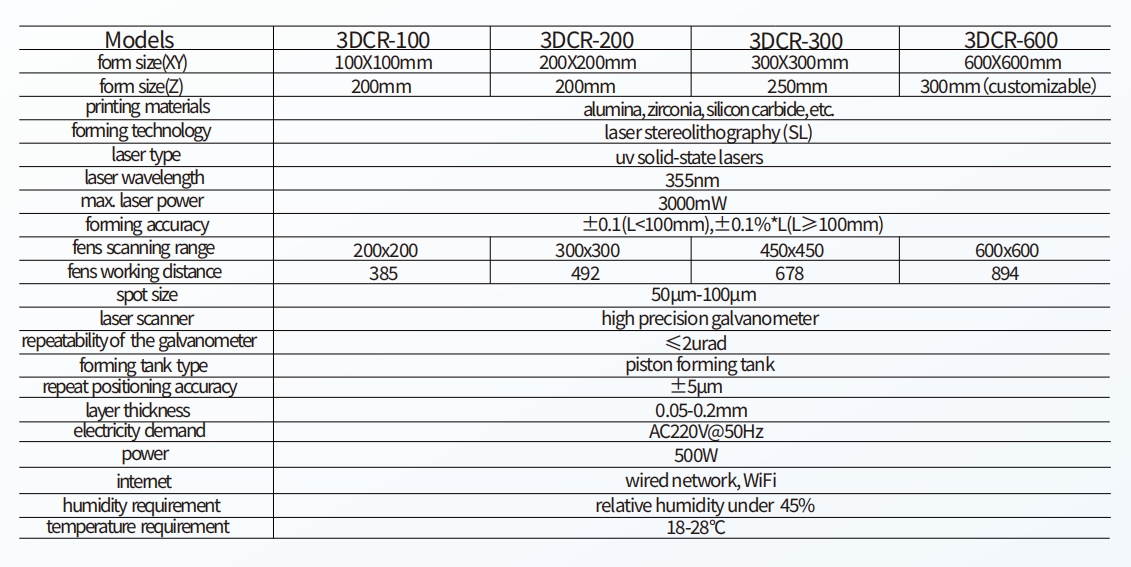

Large Forming Area

Print size from 100×100mm to 600×600mm, z-axis 200-300mm customizable.

High Efficiency

Fast printing speed, suitable for small batch production

Self-developed Material

Self-developed alumina ceramic slurry with special formula, featuring low viscosity and high solid content (85%wt).

Mature Sintering Process

Unique material formulation eliminates printing deforma tion, combined with excellent -sintering process, solves crack ing of thick-walled parts, greatly expanding the application range of ceramic 3d printing.

Support Multiple Printing Materials

Support printing of aluminum oxide, zirconia, silicon nitride and more materials.

Ceramic Printing Cases