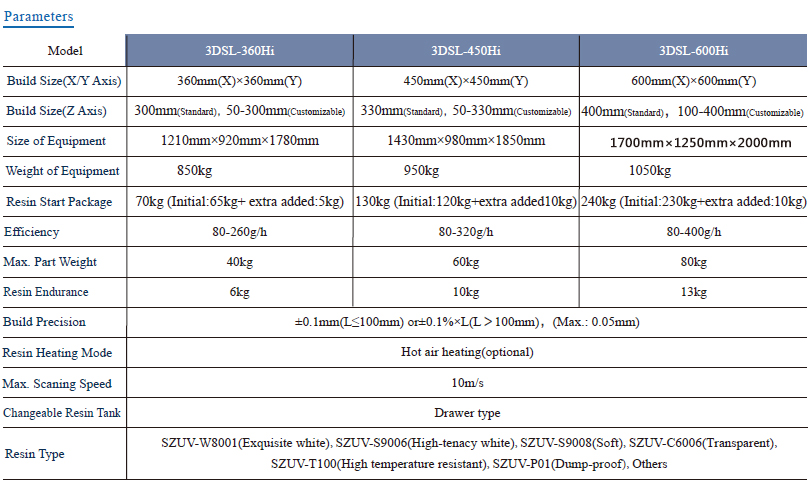

SL 3D firinta 3DSL – 450Hi

Gabatarwar fasahar RP

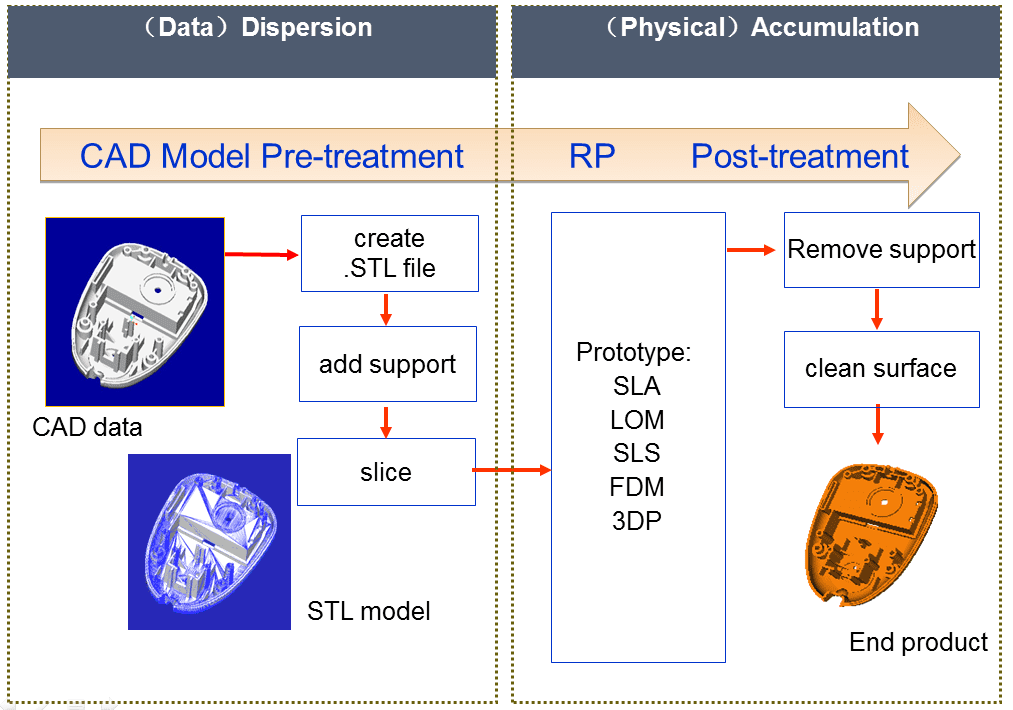

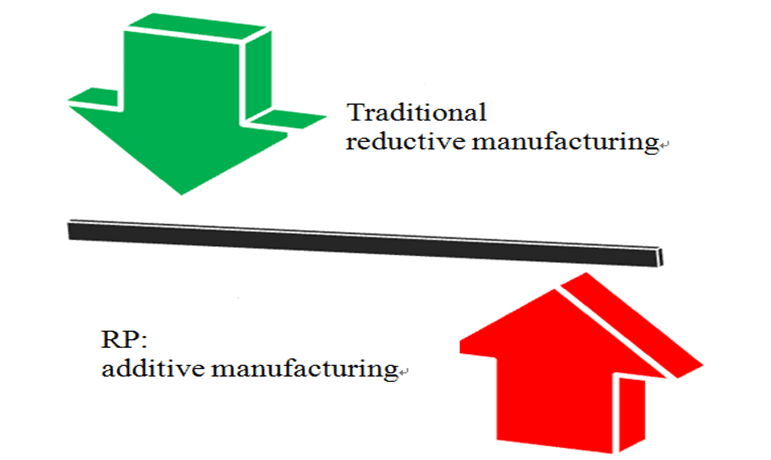

Rapid Prototyping (RP) sabuwar fasahar kere-kere ce wacce aka fara bullo da ita daga Amurka a karshen shekarun 1980. Yana haɗa nasarorin kimiyya da fasaha na zamani kamar fasahar CAD, fasahar sarrafa lambobi, fasahar laser da fasahar kayan abu, kuma muhimmin ɓangare ne na fasahar kere kere. Ba kamar hanyoyin yankan gargajiya ba, samfuri cikin sauri yana amfani da tsarin ƙirƙira wanda aka ɗora kayan da aka ɗora zuwa na'ura samfurin sashi mai girma uku. Da fari dai, software ɗin da ke sanyawa yana yanka CAD geometry na ɓangaren bisa ga wani kauri mai kauri, kuma yana samun jerin bayanan kwane-kwane. Mai kafa shugaban na'ura mai saurin ƙira ana sarrafa shi ta tsarin sarrafawa bisa ga bayanan kwane-kwane mai girma biyu. Ƙarfafa ko yanke don samar da siraran siraran sassa daban-daban kuma an sanya su ta atomatik zuwa ƙungiyoyi masu girma uku.

Ƙarfafa masana'antu

Halayen fasahar RP

Aikace-aikacen fasahar RP

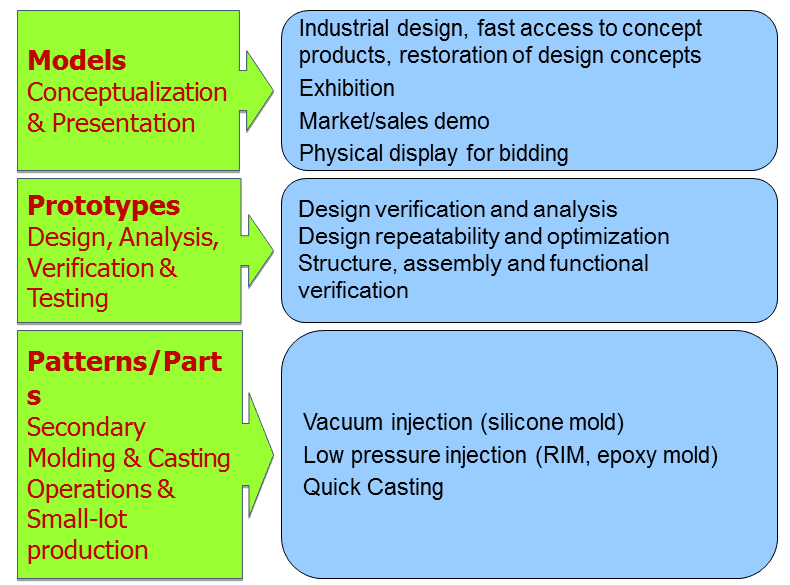

Ana amfani da fasahar RP sosai a yankunan:

Samfura (Kyauta & Gabatarwa):

Ƙirar masana'antu, saurin samun dama ga samfuran ra'ayi, maido da ra'ayoyin ƙira,Nuni, da dai sauransu.

Samfura (tsari, Nazari, Tabbatarwa & Gwaji):

Tabbatar da ƙira da bincike,Zane maimaitawa da ingantawa da dai sauransu.

Samfura/Sassan (Sakonta Na Biyu & Ayyukan Casting & Samar da Ƙaramin-yawa):

Vacuum injection (silicone mold),Low matsa lamba allura (RIM, epoxy mold) da dai sauransu.

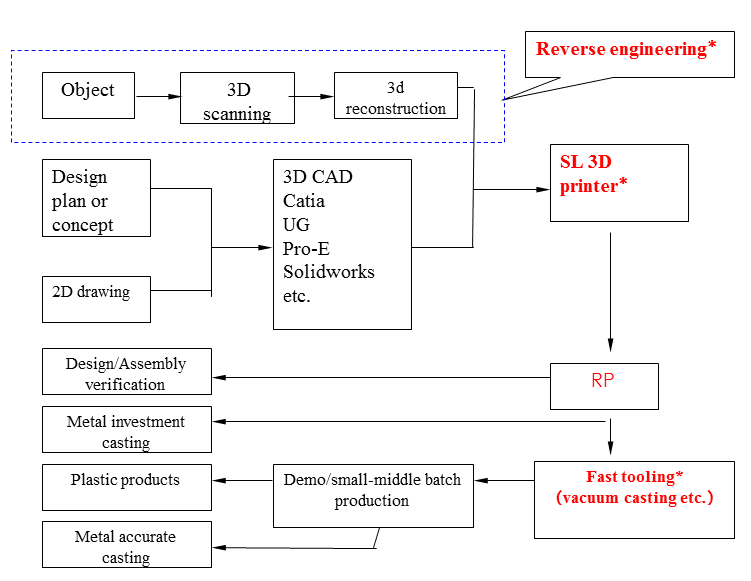

Tsarin aikace-aikacen RP

Tsarin aikace-aikacen na iya farawa ko dai daga abu, zane na 2D ko kawai ra'ayi. Idan kawai abu yana samuwa, mataki na farko shine bincika abu don samun bayanan CAD, je zuwa sake fasalin aikin injiniya ko kawai gyara ko gyara sannan fara aikin RP.

Idan zane-zane ko ra'ayi na 2D ya wanzu, ya zama dole a je tsarin ƙirar 3D ta amfani da software na musamman, sannan je zuwa tsarin buga 3D.

Bayan aiwatar da RP, zaku iya samun ingantaccen samfuri don gwajin aiki, gwajin taro ko je zuwa wasu hanyoyin yin simintin gyare-gyare bisa ga ainihin bukatun abokan ciniki.

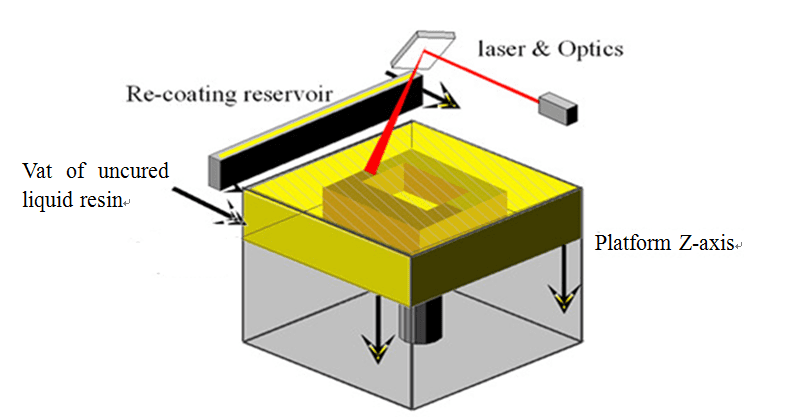

Gabatarwar fasahar SL

Sunan gida shine stereolithography, wanda kuma aka sani da Laser curing prototyping mai sauri. Ka'idar ita ce: Laser yana mai da hankali kan saman resin na ruwa na photosensitive kuma an duba shi bisa ga giciye-sashe na ɓangaren, don a zaɓa shi warkewa, daga aya zuwa layi zuwa saman, don kammala warkewar ɗayan. Layer, sa'an nan kuma dagawa dandali ne saukar da daya Layer kauri da kuma mayar da wani sabon Layer da guduro a warke da Laser har sai da dukan m model ya samu.

Fa'idar 2nd Generation na SL 3D Printers na SHDM

Tankin guduro mai sauyawa

Ciro kawai ka matsa ciki, zaka iya buga wani resin daban.

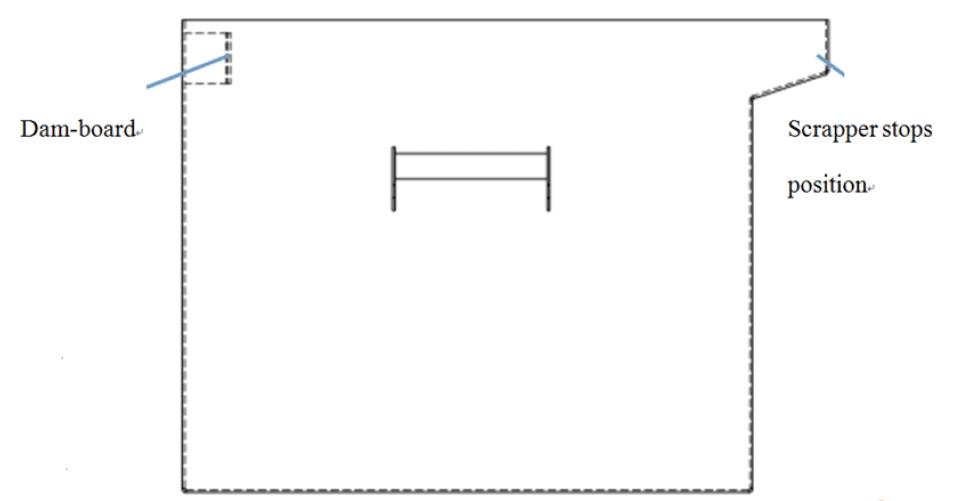

Resin tanki na jerin 3DSL yana canzawa (Sai 3DSL-800). Don firinta na 3DSL-360, tankin guduro yana tare da yanayin aljihun tebur, lokacin da ake maye gurbin tankin guduro, ya zama dole a saukar da tankin guduro zuwa ƙasa kuma ya ɗaga makullin kulle guda biyu, sannan cire tankin guduro. Zuba sabon guduro bayan tsaftace tankin guduro da kyau, sannan a ɗaga makullin kamawa sannan a tura tankin guduro a cikin firintar kuma a kulle da kyau.

3DSL-450 da 3DSL 600 suna tare da tsarin tankin guduro iri ɗaya. Akwai tarkace guda 4 a ƙarƙashin tankin guduro don sauƙaƙe fitar da turawa.

Tsarin gani-Karfin Laser mai ƙarfi

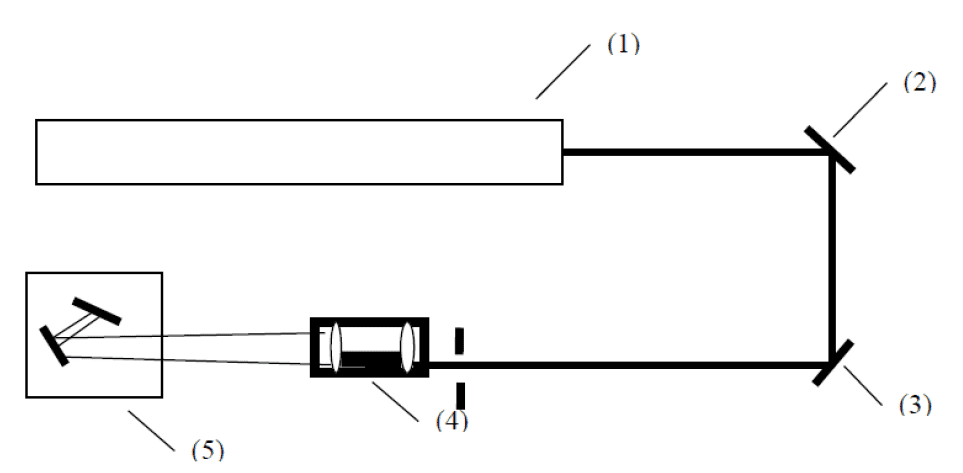

3DSL jerin SL 3D firintocinku suna ɗaukar babban na'urar Laser mai ƙarfi na3Wda ci gaba da fitarwa kalaman tsawo ne 355nm. Fitar da wutar lantarki shine 200mw-350mw, sanyaya iska da sanyaya ruwa na zaɓi ne.

(1). Na'urar Laser

(2). Reflector 1

(3). Reflector 2

(4). Beam Expander

(5). Galvanometer

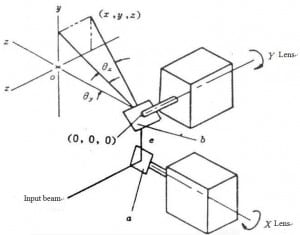

Babban inganci Galvanometer

Matsakaicin saurin dubawa:10000mm/s

Galvanometer na'urar motsa jiki ce ta musamman, ka'idar ta asali iri ɗaya ce da mita na yanzu, lokacin da wani takamaiman halin yanzu ke wucewa ta cikin nada, na'ura mai juyi zai karkata wani kusurwa, kuma kusurwar jujjuyawa tana daidai da na yanzu. Don haka galvanometer kuma ana kiransa galvanometer scanner. Galvanometer guda biyu da aka shigar a tsaye suna samar da kwatance biyu na X da Y.

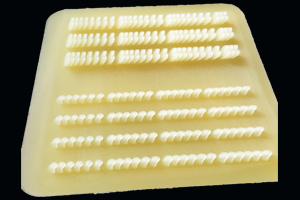

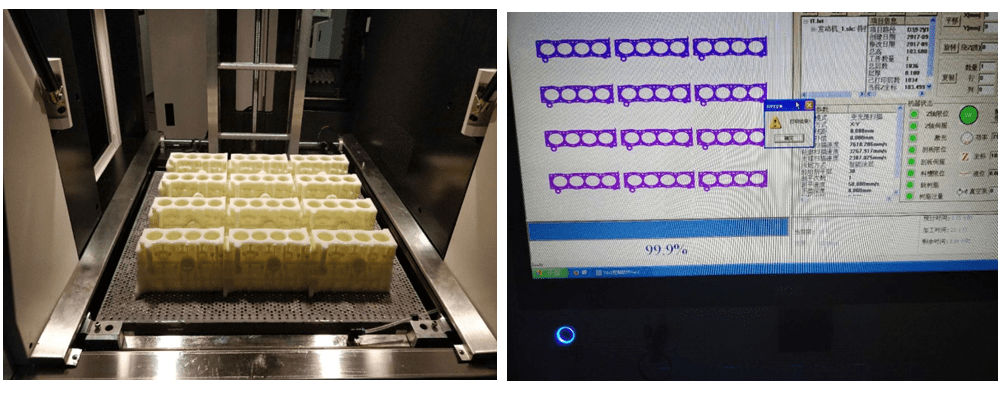

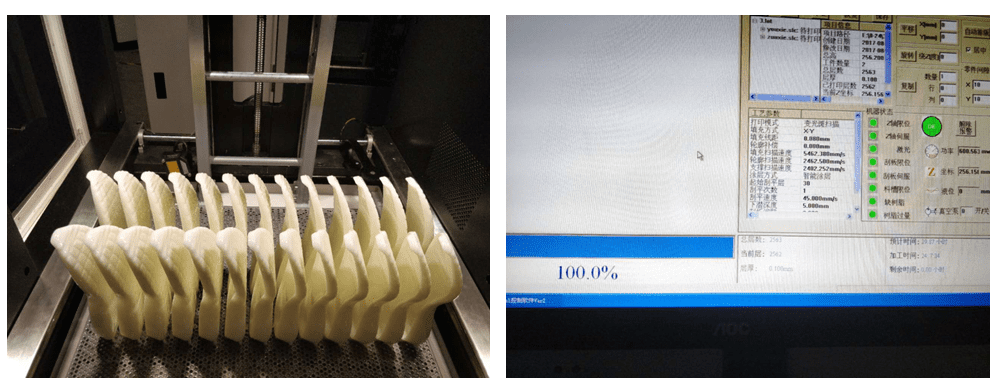

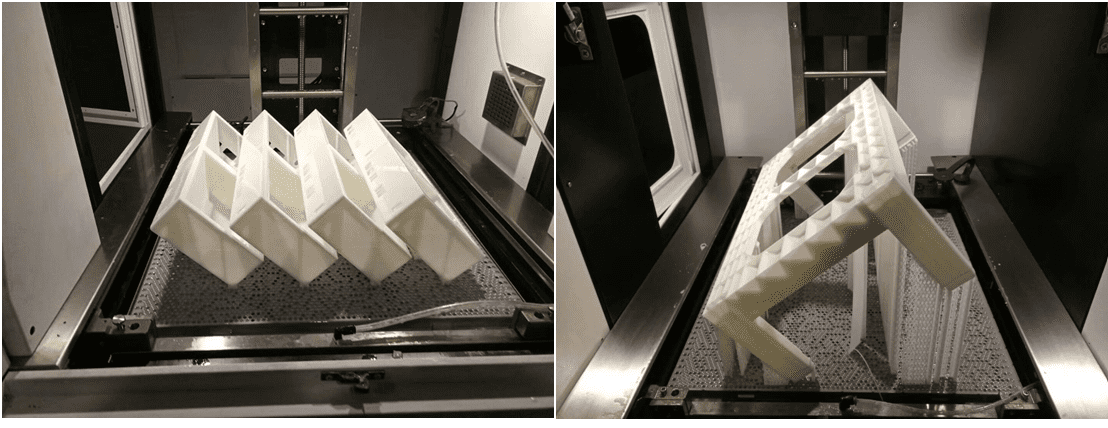

Gwajin samfura-mota toshe toshe

Sashin gwaji shine toshe injin mota, girman sashi: 165mm × 123mm × 98.6mm

Girman sashi: 416cm³, Buga guda 12 a lokaci guda

Jimlar nauyi shine game da 6500g, Kauri: 0.1mm, Gudun Gudun: 50mm/s,

Yana ɗaukar awa 23 don gamawa,matsakaita 282g/h

Gwajin yawan aiki- takalman takalma

SL 3D firinta: 3DSL-600Hi

Buga takalman takalma 26 a lokaci guda.

Yana ɗaukar awa 24 don gamawa

Matsakaici 55 minga tafin takalmi ɗaya

Zazzage ƙasidar

Yankunan aikace-aikace

Ilimi

Samfura masu sauri

Motoci

Yin wasan kwaikwayo

Zane-zane

Likita

Tsari:

|

Tsarin Laser | Nau'in Laser | Tsayin Laser | Ƙarfin Laser (fitarwa) | |

| Laser mai ƙarfi | 355nm ku | ≥500mw | ||

|

DubaningTsari | Duba Galvanometer | Laser BeamDiamita | Yanayin Mayar da hankali | |

| SCANLAB(an shigo da shi) | Variiyawakatako0.1-0.5mm | Lens na F-theta | ||

|

RecTsarin oating | RecYanayin oating | Recoating Kauri | ||

| Vacuum Matsayin Hankali tsotsaTufafi | 0.03-0.25mm (Na al'ada:0.1mm; Daidaito:0.03-0.1mm;Babban Gudu:0.1-0.25mm) | |||

|

Tsarin ɗagawa | Motar dagawa | Ƙaddamarwa | Maimaita Matsayi Ƙaddamarwa | Datum Platform |

| High Precision ACServo Motor | 0.001mm | ± 0.01mm | Marmara | |

|

Software muhalli | Tsarin Aiki | Software na sarrafawa | Interface Data | Nau'in Intanet |

| WindowsXP/Win7 | Farashin 3DSLCON | STL/SLC fayil format | Ehternet TCP/IP | |

|

Wurin Shigarwa | Ƙarfi | Yanayin Zazzabi | Humidity na Muhalli | |

| AC220V,50HZ,16A | 24-28 ℃ | 20-40% | ||